How is a Mats4U Heavy Duty Logo Mat made?

- Mats4U Blogger

- Blog

- 13 Oct 2017

- views

Have you ever been curious about the transformation of the design into an actual logo mat?

Allow us to unveil the incredible journey that each logo mat undergoes before finding its place on your floor, proudly showcasing your unique logo or brand.

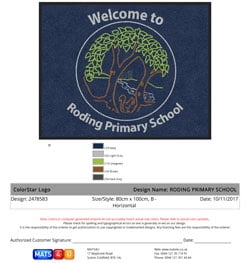

Design

The initial step in creating a logo mat involves designing the mat itself. Simply provide your logo and colour preferences, an our talented designer will take care of the rest. Once the design is ready, you'll receive a digital proof showcasing how the mat will appear.

If you're satisfied with the proof, the production process commences for your logo mat. However, if you wish to make any adjustments to the colours or layout, you have the freedom to do so. Feel free to request as many design modifications as you desire before the mat enters the production phase.

The Mat Face

The surface of your logo mats begins as a simple, plain carpet.

This carpet is crafted using P.E.T yarn, which incorporates 50% recycled content from post-consumer sources.

This groundbreaking P.E.T. material enhances the mat's resistance to stains and UV rays, surpassing the capabilities of nylon yarn. Additionally, P.E.T. yarn excels at retaining dirt and absorbing moisture, ensuring optimal performance.

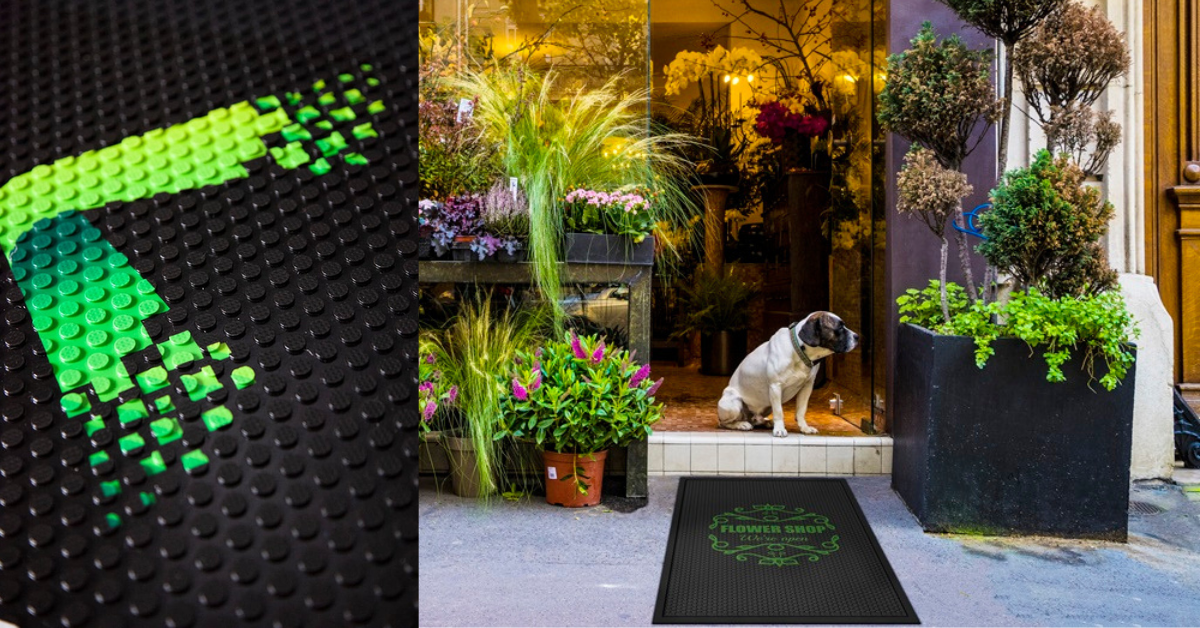

Printing

Now, let's delve into the most thrilling phase, as your mat embarks on its journey through our cutting-edge, high-definition printer!

This advanced printer is where the design is meticulously transferred onto the mat's surface using dye capable of producing an impressive spectrum of up to 60 different colours.

The dye penetrates deep into the fabrics, ensuring that the colour retains its vibrancy even in areas with heavy foot traffic.

On average, each mat spends approximately one hour being processed, including printing and drying, on this remarkable machine.

Once the mat completes its passage through the printer, it emerges fully printed, completely dry, and ready to be backed for the next stage.

Backing

The face of the mat is carefully affixed by hand to a robust nitrile rubber backing, which is then subjected to high temperatures in an oven. This process ensures seamless integration of the rubber backing with the carpet.

After the mats have cooled down, precise trimming is performed on the edges, resulting in a polished final appearance. Following this, the mats are meticulously packaged and swiftly dispatched to their designated destination, all within a timeframe of just 7-10 working days.

And there you have it - the complete journey of a logo mat, from its initial stages to the final produce. To witness the entire process in action, we invite you to view the video below

How Our Heavy-Duty Logo Mats Are Made.

Want your very own Logo Mat?

Get the ball rolling and request your free proof from Mats4U today by completing the Logo Mat Order Form. Alternatively, if you would like some advice or have any questions, please do not hesitate to call us on 0121 313 6748 or email [email protected]. We are available Monday-Friday from 9am-5pm and would be more than happy to help.